Building Knowledge

Panelized Facades and the Path Forward in Modular Construction

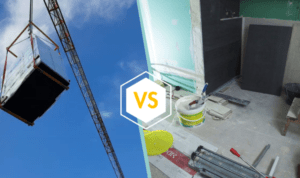

As modular construction evolves, panelized facades can significantly advance offsite building practices, particularly in retrofit applications aimed at improving energy efficiency and reducing timelines. While Europe leads in adopting complete wall systems with pre-installed elements such as windows and cladding,