Building Knowledge

Prefabricated Bathrooms and Kitchens

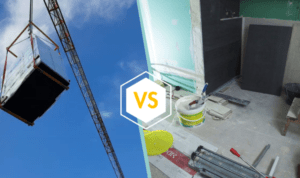

Prefabricated bathrooms and kitchens represent a growing trend in offsite construction, with significant applications in commercial and institutional projects. This post examines the market’s current state, focusing on European manufacturers like Baudet and HVA Concept, as well as U.S. companies